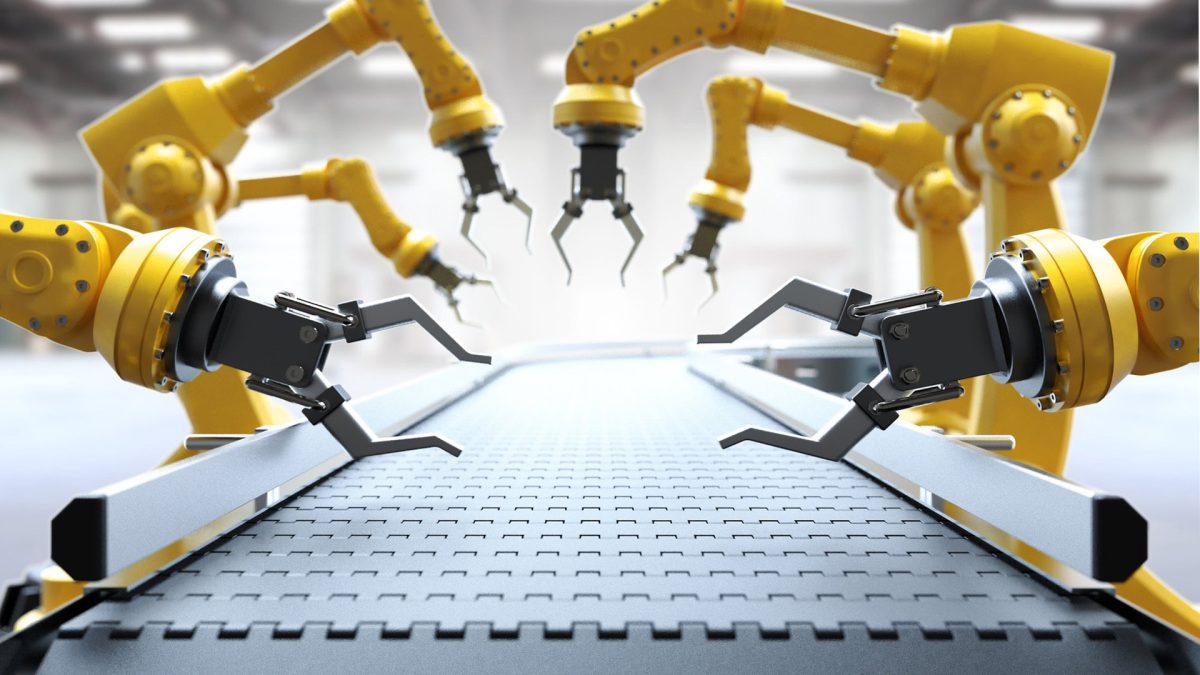

In today’s fast-paced manufacturing industry, the convergence of AI, robotics and advanced automation is reshaping the landscape. The future factory is no longer a distant concept but a tangible reality, where intelligent machines work hand in hand with human operators to optimise production processes, enhance and deliver unparalleled quality. However, to unlock the full potential of this technological revolution, a robust network infrastructure becomes the critical link that connects and harmonises these transformative technologies. In this article, we explore the realm of AI, robotics, and the future factory, highlighting the essential role of seamless integration and unleashing the full power of automation.

“The Internet of Robotic Things (IoRT) is revolutionising how automation and robotics work by allowing seamless connectivity and data exchange between machines. With IoRT, robots can receive instructions, exchange data, and coordinate with other machines, resulting in efficient and flexible manufacturing processes,” said Sameer Mahapatra, Country Manager, India & SAARC, Aeris Communications. Sameer explains further, “IoRT’s impact extends to healthcare and transportation, driving safety and productivity. Sameer elaborates on the benefits, including enhanced efficiency, quality control, and operational performance. With rising production demands, seamless integration of robotics and automation optimises resource utilization to meet growing needs effectively.”

Ashok Leyland’s President and Chief of Operations, Ganesh Mani, highlights the transformative role of IoRT in the automotive industry. Integrating robots, sensors, and AI can optimise plant production processes, resulting in safer and more efficient vehicle manufacturing. Autonomous vehicles are a key component of IoRT’s impact on the industry, with automotive companies worldwide implementing automated vehicles as technology advances. The automotive sector in India sees IoRT as the next phase of industrial evolution, revolutionizing the way vehicles are produced and operated.

Robotics has long been an integral part of the manufacturing industry, automating repetitive tasks, increasing productivity, and ensuring precision. Integration of robotics, automation, IoT, cloud computing, and big data analytics fuels the development of intelligent, efficient, and collaborative robots, as stated by UiPath’s Rohit Kumar, APJ Manufacturing Lead. IoRT has immense potential to revolutionise the landscape of automation and robotics in numerous impactful ways:

- Enhanced connectivity: IoRT enables robots to communicate with each other and with other devices and systems. This connectivity enhances their ability to perform complex tasks and collaborate with humans, resulting in more efficient and effective automation processes.

- Intelligent decision-making: IoRT facilitates the integration of AI & ML algorithms into robotics, enabling them to make intelligent decisions based on real-time data. This capability is critical for robots that operate in dynamic environments where conditions are constantly changing.

- Increased efficiency: IoRT enables robots to share data with other devices and systems, optimising their performance and reducing energy consumption. This capability is critical for robots that operate in large-scale manufacturing and logistics environments.

- Improved safety: IoRT enables robots to operate more safely in shared spaces with humans. For example, collaborative robots (cobots) that use IoRT can detect the presence of humans and adjust their behaviour accordingly, reducing the risk of accidents and injuries.

Lalit Kumar Mishra, Country Head (Indian Subcontinent) at Cognex Inc, explains that the integration of physical robots with the internet through IoRT facilitates real-time data exchange, remote control, and intelligent decision-making. This technology optimises industrial processes across manufacturing, healthcare, logistics, and agriculture, enabling precision, scalability, and operational agility. The future of automation and robotics is shaped by IoRT’s limitless possibilities, fostering an intelligent, interconnected, and automated world. Sensor manufacturers, including machine vision suppliers, will play a crucial role in enabling this transformation.

The synergy between these technologies drives innovation, efficiency, and productivity. However, challenges such as standardization of communication protocols, interfaces, and robust cybersecurity measures must be addressed to integrate and safeguard interconnected systems from potential threats successfully.

The synchronization of robotics and AI-powered automation is crucial in facilitating seamless and optimised operations across industries in the era of generative AI. Lalit explains, “The synergy between robotics and automation drives innovation and efficiency across industries. The seamless collaboration of these technologies streamlines processes, enhances productivity and unlocks new possibilities. However, several challenges must be addressed to achieve this synchronization. Firstly, standardisation of communication protocols and interfaces is crucial for seamless integration between robotic systems and automated processes. Additionally, ensuring robust cybersecurity measures to safeguard interconnected systems from potential threats is imperative. Additionally, advancements in AI and ML algorithms are needed to enhance these technologies’ adaptability and decision-making capabilities. Lastly, effectively upskilling the workforce to operate and maintain these integrated systems is vital for successful implementation. Overcoming these challenges will foster a harmonious collaboration between robotics and automation, unlocking a future where technology amplifies human potential and accelerates progress.”

It is very vital that both robotics and automation work in sync since both are cyber-physical systems operating in the physical world alongside human beings, with human safety being primordial. Ganesh points out, “However, for robotics and automation to work seamlessly, there are several challenges that must be addressed; in my view, (i) Machines compatibility & their interoperability (ii) Cybersecurity and agility towards software & hardware updates (iii) Safety, more sophistication entails more safety equipment’s installation for the safety of operators (iv) Maintenance, failure to upkeep can lead to downtime & safety incidents (v) Operators training.”

Sougandh K.M., Sales Development Manager at Universal Robots, acknowledges the undeniable benefits of collaboration between robotics and automation. However, there are challenges that must be addressed to ensure the seamless and optimal utilization of this strategy.

|